Chyba formátu e-mailu

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Novinky

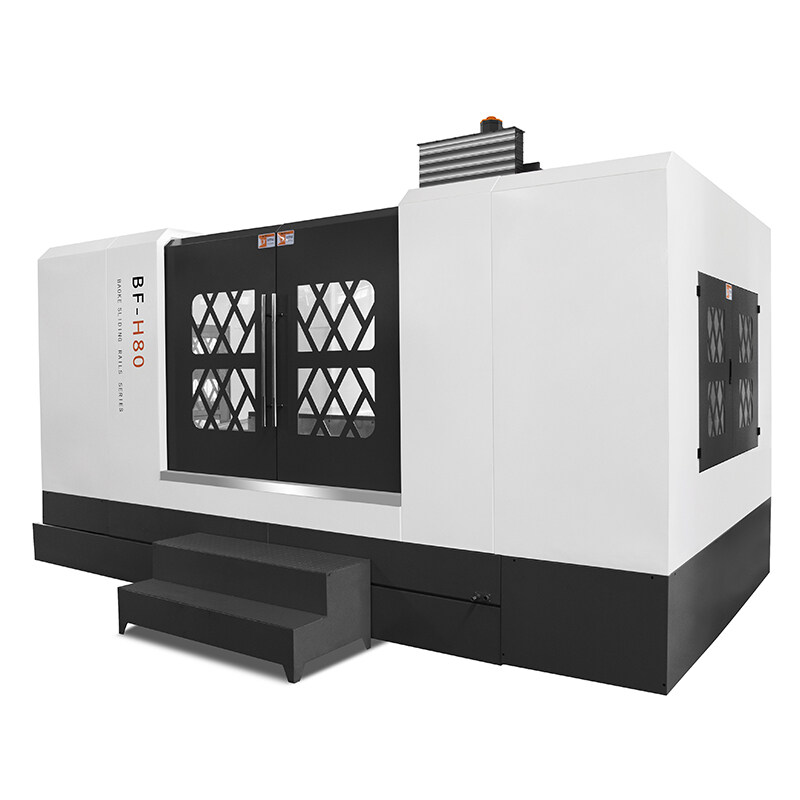

How to Distinguish between Vertical Machining Center and Gantry Machining Center?

Features of vertical machining center:

- Environmental protection and no pollution. Because there will be no oil and fog spray, and the surrounding environment will not be polluted;

- Accurate oil supply. By adding a regulating valve, the oil can be delivered to the lubrication points such as the main shaft and the lead screw according to different needs;

- There is no problem with difficult atomization of high viscosity lubricating oil; Suitable for any oil;

- Automatic detection and monitoring. It can detect whether the lubricating oil is normal. If the lubrication is poor, it can alarm and stop the machine to avoid the abnormal operation of the equipment;

- It is especially suitable for the rolling bearing of the main shaft, which has a certain air cooling effect, and can reduce the operating temperature of the bearing, to prolong the service life of the main shaft;

- Low fuel consumption and cost-saving.

Gantry machining center features:

- Workbench

The worktable of the gantry machining center is rectangular. Large castings such as workbench, bed, column, cross beam, and RAM are made of cast iron or weldments. The inner cavity of the castings is a honeycomb composite arrangement structure, with advanced design. They are all treated with aging and secondary tempering to eliminate residual internal stress and stabilize the material, to ensure the stability of workpiece processing accuracy and the service life of the machine tool.

- Longmen

The gantry is composed of a beam and two columns. It can be divided into three types: beam fixing, beam locking and sectional lifting by positioning block, and beam arbitrary lifting.

- Ram

The ram can be divided into open type and closed type in structure. The ram with an open structure is clamped on the headstock through the pressing plate, and the sectional area of the ram is large; The ram with a closed structure is clamped in the spindle box, and the sectional area of the ram is small.

- Tool magazine

The basic types of tool magazines include turret type, wheel drum type, and chain length type.

- Attachment header library

The machining of large and complex parts usually requires many attachment heads. The accessory head is specially designed according to the processing requirements of the workpiece, which is generally divided into right angle head, extended head, special angle head, and universal head.

- Numerical control system

There are many suppliers of CNC systems, and there are different choices of system brands and models according to different needs.

- Accuracy

The accuracy of the machine tool refers to the original accuracy of the machine tool without external load. Accuracy is usually expressed by the deviation between its opposite side and the ideal state (error for short). The smaller the error, the higher the accuracy.

How to distinguish between vertical machining center and gantry machining center?

- The supporting structure is different:

A vertical machining center refers to the machining center whose spindle axis is set perpendicular to the workbench. The vertical X and Y axes are combined, and the Z-axis moves up and down the column, which is suitable for small precision mold and parts processing. The larger Lijia is about 4 meters long, and the model can be determined according to the specific material processed.

Gantry machining center refers to the machining center whose spindle axis is perpendicular to the workbench. The z-axis support structure of the gantry is different, and the y-axis is horizontally laid between the two columns, which increases the load and processing range of the workbench.

- Different uses:

A gantry machining center is mainly suitable for processing large parts. The vertical machining center is mainly suitable for processing complex parts such as plates, plates, molds, and small shells.

Make a purchase of used vertical machining center, vertical machining center price, vmc vertical machining center from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.